PRODUCT CATEGORY

CONTACT US

- Tel: 0086-311-89642206

- Fax: 0086-311-67906676

- Mobile: 0086-15076331069 13933856228

- E-mail: sales@hbmetals.com

- E-mail: info@hbmetals.com

Basic Knowledge of Steel Pipes 02

2. Seamless Pipe

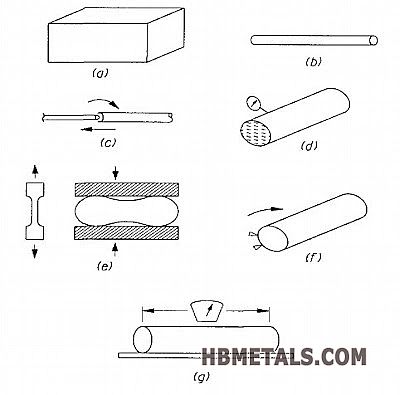

Seamless pipe is fabricated by piercing a hot cylindrical billet and forming a seamless tube. The "seamless" fabrication process follows several steps, depending on the applicable material specification. These steps typically include the operation shown in the figure below:

a) a forging is heated to white metal temperature, b) the white hot ingot is forged and elongated into cylindrical bars, c) the white-hot bars are pierced and sized to the right diameter and thickness, d) the pipe is hydrotested, e) mechanical properties are verified against the material and procurement specifications, f) the ends are beveled or threaded, and g) the pipe is cleaned, marked and readied for shipment. Alloys such as stainless steels would be passivated(pickling and descaling) by immersion into a warm acid bath, followed by water rinse and drying in air(passivation), the pipe is then measured weighed and marked.

3. Seam Welded Pipe

Welded pipe is made from skelp(the name given to plate used in pipe fabrication) deformed in an O-shape or spiral shape, then welded along a longitudinal or spiral seam. There are several types of seam welded steel pipe: electric resistance welded pipe, furnace butt welded pipe, arc welded pipe, electric flash welded pipe, and double submerged arc welded pipe. Electric resistance welded pipe(ERW) is made from plate, longitudinally butt welded by heat from electric current, without filler metal. Furnace butt welded pipe is made from a heated plate drawn through a welding bell and butt welded by compression of the plate edges in the hot furnace. Arc welded pipe is made from plate butt welded by manual or automatic arc, with single or multiple passes on the outside diameter(O.D.) and inside diameter(I.D.), with or without filler. Electric flash welded pipe is made from plate, longitudinally butt welded by the heat from electric resistance. Double submerged arc welded pipe is made by the submerged arc welding process, typically with passes on the O.D. and I.D.

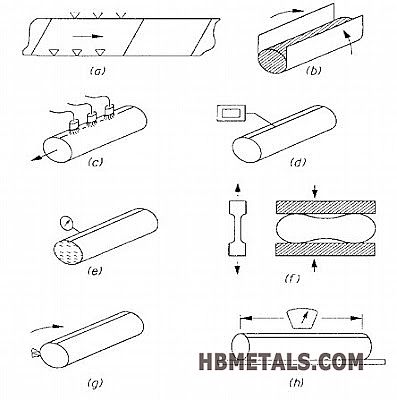

The fabrication process of seam welded pipe follows the steps illustrated in the figure below:

a) steel plates(skelp) are welded end to end and rolled into coils, the out edges are beveled, b) plates are bent progressively on a pipe mill into a U then O shape, c) the seam is welded and then treated(typically by induction and gas furnace annealing), d) the weld is inspected (depending on the material specification, seam inspection may be as little as visual or as much as 100% radiography), e) the pipe is hydrotested, f) mechanical properties are verified for weld and base material, including tensile properties(yield stress, ultimate strength and elongation at rupture) and ductility by ring crush. g) the ends are beveled or threaded, h) the pipe is cleaned(pickling for stainless steel), measured, weighed and marked. Note that for 6" and larger pipe, a seam welded pipe with 100% radiography can be a cost-effective alternative to a seamless pipe.

From the 1920's to as late as the 1980's in some pipe mills, line pipe(API 5L) was seam welded using low frequency ac current(360Hz) or dc current. Under these conditions, there must be a very close contact between the electrode and the skelp to achieve continuous fusion. That is why some pipes fabricated during that period exhibit lack of fusion along the seam, referred to as cold welds or stitched welds. The condition is practically inexistent in modern seam welded pipe using high frequency ac current(in the order of 450KHz).

Views: Author:METALS INDUSTRIAL Date:06/11/27