PRODUCT CATEGORY

CONTACT US

- Tel: 0086-311-89642206

- Fax: 0086-311-67906676

- Mobile: 0086-15076331069 13933856228

- E-mail: sales@hbmetals.com

- E-mail: info@hbmetals.com

Basic Knowledge of Stainless Steel Sheet, Plate and Strip

1. Introduction to Stainless Steel Sheet, Plate, Strip and Coil

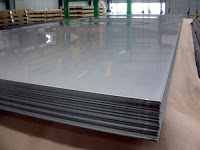

A stainless steel sheet / plate is a typical sheet metal formed by an industrial process into thin, flat pieces. They are widely used in building construction, medical table, decoration, home appliance, auto mobile and air conditioning systems, etc. In fact, the terms "sheet" and "plate" are confusing. Both of them are flat-rolled metal products of some minimum thickness and width arbitrarily dependent on the type of metal. The thicknesses of stainless steel plates are commonly equal to or larger than 5 mm(3/16") with widths larger than 250 mm(10"). A stainless steel sheet has a thickness under 5 mm(3/16") while its width is equal to or larger than 600 mm(24"). The flat piece with thickness under 5 mm(3/16") while its width is under 600 mm(24") is considered as stainless steel strip. Stainless steel sheet can be supplied in flat pieces or coiled types. The stainless steel coils are formed by running a continuous stainless steel sheet or strip through a roll slitter.

Stainless steel sheet possesses untarnished surface appearance and corrosion resistance as its main advantages. It can be welded and cut without damaging its corrosion resistance. Compared with galvanized steel sheet, stainless steel sheet is very tough, but it can still be readily worked in sheet metal workshop.

2. Gauge Standards for Stainless Steel Sheet, Plate and Strip

3. Fabrication Process of Stainless Steel Sheet, Plate & Strip

4. Material Selection of Stainless Steel Sheet, Plate and Strip

5. Surface Finishes of Stainless Steel Sheet, Strip and Plate

Views: Author:hbmetals Date:15/07/01