1. Flare tests for nickel and nickel-alloy seamless pipes

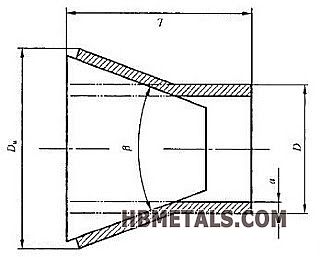

The flare test shall consist of flaring a test specimen with an expanding tool having an including angle of 60° until the specified outside diameter has been increased by 30%. The flared specimen shall not exhibit cracking through the wall.2. Hydrostatic tests for nickel and nickel-alloy seamless pipes

Each nickel or nickel-alloy seamless pipe shall be tested by the manufacturer to an internal hydrostatic pressure of 1000 psi (6.9MPa) provided that the fiber stress, calculated from the following equation, does not exceed the allowable fiber stress for the material:

P = 2St/D

P = hydrostatic test pressure, psi(MPa).

S = allowable fiber stress, for the material in the condition (temper) furnished as specified in the product specification.

t = minimum wall thickness permitted, inch(mm), including minus tolerance, if any.

D = nominal outside diameter of the nickel or nickel-alloy seamless pipe, inch(mm).

The test pressure must be held for at least 5 seconds.